Modular Power Supply Solutions for Military R&D: Enabling High-Precision Radar, Signal Generators, and Oscilloscopes

1. Stringent Power Demands in Military R&D Test Systems

Military research institutes and defense technology laboratories rely on highly specialized test systems such as radar, signal generators, and oscilloscopes, each requiring high-precision, high-reliability power delivery. These power systems are subject to conditions far beyond typical commercial applications:

1.1 Challenges in Harsh Military Environments

-

Temperature Extremes: Operating range from –55°C to +85°C, requiring components with extended temp ratings (MIL-PRF-27, MIL-STD-202).

-

Electromagnetic Compatibility (EMC): Must meet MIL-STD-461G, especially for EMI-sensitive systems like RF generators.

-

Shock and Vibration: Tested under MIL-STD-810H protocols for airborne, naval, or field deployment environments.

-

Power Line Disturbances: AC/DC line must tolerate brownout, surge, conducted emissions per DO-160G Section 16/18.

Reference: U.S. Department of Defense Test Method Standard – MIL-STD-810H

(Source)

1.2 Modular Power Supplies vs. Traditional Architectures

| Feature | Traditional Linear PSUs | Modular Power Supplies (MPS) |

|---|---|---|

| Scalability | Fixed topology | Easily parallel/series configurable |

| Thermal Management | High heat dissipation | Efficient topology (ZVS/ZCS) + cooling |

| EMC Performance | High emission due to transformers | Optimized layout + EMI filters |

| Dynamic Load Response | >1ms recovery time | <100µs with current-mode control |

| Redundancy / MTBF | <50,000 hrs | >100,000 hrs (typical) |

Source: Vicor Corporation – “High Density Modular Power Systems in Defense Electronics”

(Read whitepaper)

1.3 Power Requirement Matrix – Typical Equipment

| Equipment | Output Requirement | Special Design Consideration |

|---|---|---|

| Radar System | 28V / 270V DC @ up to 50kW | Nanosecond-level load response, phase-synchronized power pulses |

| Signal Generator | ±15V / ±12V DC, <5mVp-p ripple | Critical for signal purity at 40GHz+, phase noise < -110 dBc/Hz |

| Oscilloscope | Multiple voltage rails ±12V, +5V, +3.3V | Rail-to-rail drift <0.1%, ADC resolution protection for 12-bit+ bandwidth |

2. Deep Technical Analysis: Radar Power Systems

Radar platforms – including airborne fire control, naval tracking, and land-based surveillance – impose some of the most complex electrical requirements. These systems often rely on pulse loads, high-voltage DC buses, and real-time synchronization with system clocks.

2.1 Power Architecture of Phased Array Radar

Architecture Comparison:

| Approach | Centralized HVDC Bus | Distributed Regulation Near Load |

|---|---|---|

| Pros | Low I²R loss over long distance | Fast response near T/R modules |

| Cons | Requires heavy cabling + shielding | Increased local EMI risk, thermal hotspots |

| Use Case | Shipborne radar @540V DC | AESA radar with >1000 T/R modules |

Real-World Example: AN/SPY-6 radar uses distributed GaN amplifier modules with localized DC-DC converters.

Source: Raytheon Technologies White Paper (link)

2.2 Pulse Load Compensation – Energy Storage Design

Pulse Load Formula for Radar Modules:

C≥τ⋅Ipd⋅U0C \geq \frac{\tau \cdot I_p}{d \cdot U_0}

Where:

-

C = minimum capacitance required

-

τ = pulse width (e.g., 10 µs)

-

Ip = peak current (e.g., 200A)

-

d = allowable voltage drop (e.g., 5%)

-

U₀ = nominal supply voltage (e.g., 270V)

A 200A pulse for 10µs at 270V with 5% droop needs >1,480µF of low-ESR capacitance at each T/R module.

Reference: IEEE Radar Conference 2022, “Pulse Load Power Compensation in AESA Systems”

(DOI)

2.3 Radar Power Supply Case Studies

| Radar Type | Power System Features |

|---|---|

| Airborne Fire-Control | 3kVA modular system, 27VDC input, weight < 20kg, ≥82% efficiency, convection-cooled |

| Naval Early Warning | 10–50kW redundant architecture, anti-corrosive design, MTBF > 100,000 hrs |

| Weather Radar Transmitter | Liquid-cooled 30kW supply, ripple <20mVp-p, MIL-STD-810F certified |

3. Precision Power Solutions for Signal Generators

Signal generators, especially those operating at microwave frequencies (>40 GHz), demand exceptionally clean and stable power rails to preserve signal integrity. Even minute power supply ripple or cross-channel interference can lead to measurable phase noise degradation and harmonic distortion.

3.1 Noise-Sensitive Design Architecture

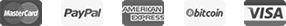

To achieve power supply ripple levels below 5mVp-p, modern signal generators adopt a multi-stage filtering architecture, as illustrated in the diagram below:

Figure: Signal Generator Power Filter Architecture

-

PFC (Power Factor Correction): Shapes the input current waveform and improves efficiency.

-

π Filter Stage: Attenuates high-frequency switching noise and differential mode EMI.

-

DC-DC Converter (Switching Pre-Regulation): Provides voltage transformation and isolation.

-

LDO Regulator: Final linear stage ensures ultra-low noise output (<5mVp-p), critical for LO chain.

Reference: Keysight Technologies, “Designing Low-Noise Power Supplies for RF Instruments”

Download Whitepaper

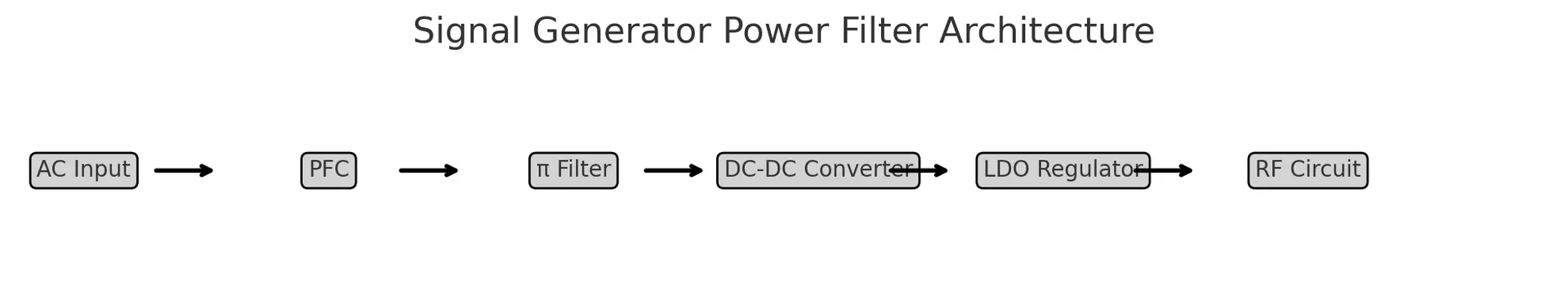

3.2 Isolation to Prevent Channel Crosstalk

For multi-channel digital modulation sources, power rail isolation is essential to prevent cross-channel modulation distortion. Each signal path typically receives its own isolated DC-DC power supply, designed with:

-

Transformers with split bobbin or shielded cores

-

High common-mode rejection filters

-

Careful PCB layout with independent ground planes

Performance Comparison:

| System Type | Crosstalk Level |

|---|---|

| Traditional Power Supply | –65 dBc |

| Modular Isolated Supply | –92 dBc ✅ |

(See Figure: Channel Crosstalk Performance Comparison)

Data Source: Rohde & Schwarz White Paper, “Power Integrity in Microwave Signal Generators”

Source

3.3 Application Case Studies

| Use Case | Power Design Details |

|---|---|

| Microwave Signal Generator | Hybrid SMPS + LDO, ripple <5mVp-p, supports >40GHz, output impedance <10mΩ |

| Field-Portable Generator | AC input: 85–264V wide range, integrated Li-ion backup battery (runtime ≥ 4 hrs) |

| High-Power RF Amplifier | 5kW water-cooled DC system, interleaved phase topology, >90% efficiency |

These systems must be rugged, lightweight, and EMI-quiet – all characteristics where modular power systems significantly outperform conventional linear PSUs.

4. Power Design for Oscilloscopes and Precision Measurement Equipment

Modern high-performance oscilloscopes used in military and aerospace testing require ultra-low noise, multi-domain power isolation, and extreme stability to ensure accurate waveform capture under harsh conditions. These requirements are especially critical in high-bandwidth models (>1 GHz) used for electromagnetic pulse (EMP) characterization, underwater acoustic signature analysis, and aerospace flight data recording.

4.1 Core Power Demands in High-Bandwidth Oscilloscopes

1. Noise Suppression at the Microvolt Level

Noise from power supplies directly impacts the oscilloscope’s vertical resolution, especially when ADCs exceed 12 bits.

Example: To maintain 12-bit resolution at a 1V full-scale range, each LSB equals ≈ 244 µV.

If power supply ripple or ground noise exceeds 10–20 µV, resolution is compromised.

Techniques:

-

Multilayer PCB stack-ups with analog/digital plane separation

-

Magnetic bead filtering at each power domain entry point

-

Point-of-load (POL) regulators placed close to sensitive ADC circuits

2. Bandwidth vs Noise Trade-off

The noise spectral density typically increases with bandwidth, due to wider input noise integration range. Below is the trend:

| Bandwidth (MHz) | Noise Spectral Density (μV/√Hz) |

|---|---|

| 100 | 1.0 |

| 500 | 1.3 |

| 1000 | 1.8 |

| 2000 | 2.5 |

| 4000 | 3.6 |

| 6000 | 4.4 |

| 8000 | 5.2 |

🔎 Interpretation: As bandwidth increases from 100 MHz to 8 GHz, the noise floor rises over 5×, demanding stricter noise suppression from the power system.

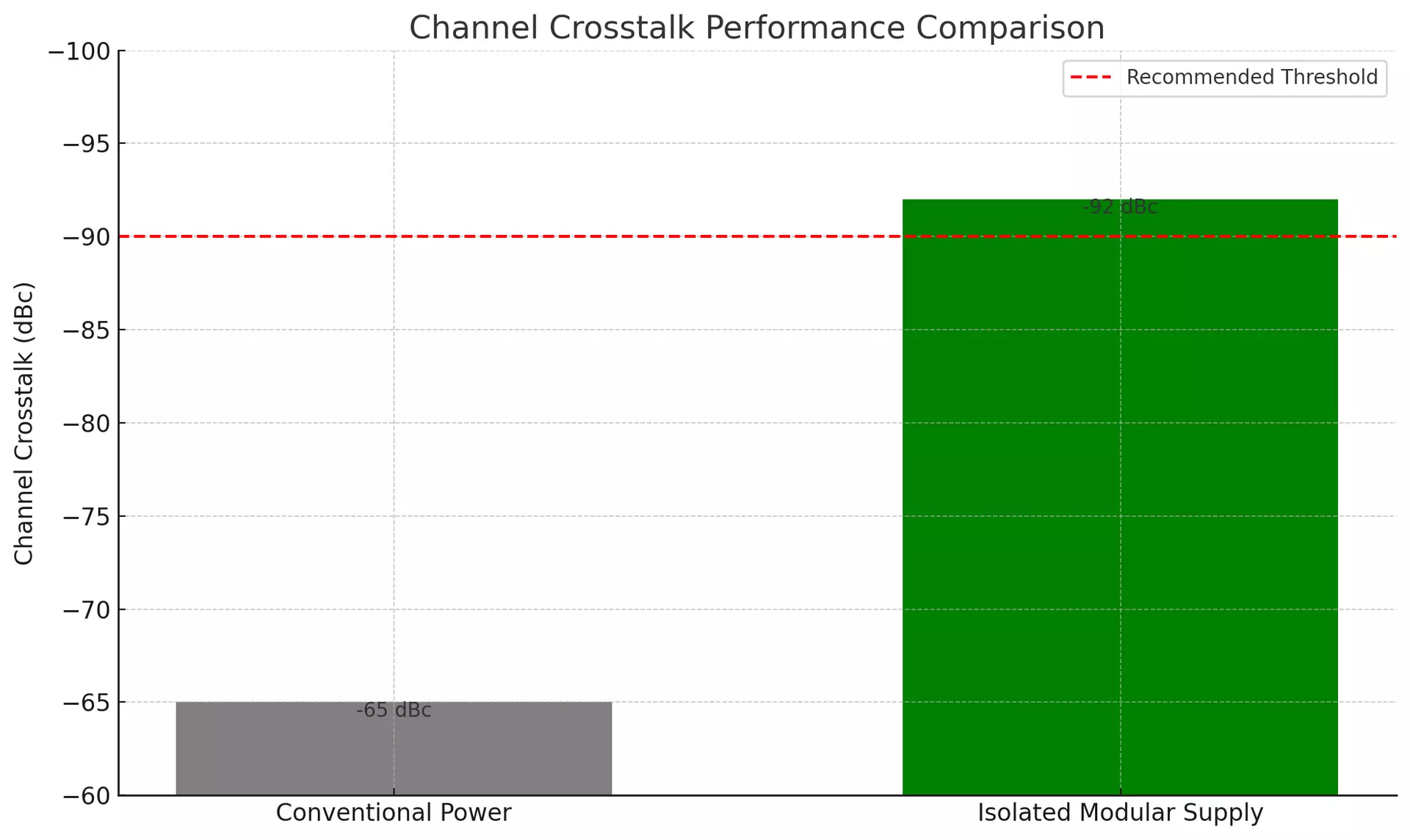

4.2 Power Domain Isolation Strategy

To prevent signal coupling between analog front-end (AFE), digital processing, and high-resolution display systems, modern scopes deploy independent power domains.

Power Isolation Architecture Overview:

(Refer to previous diagram: “Oscilloscope Power Domain Isolation Architecture”)

-

Analog Domain: ±12V low-noise supply with <3 μV/√Hz density

-

Digital Domain: +3.3V / +1.8V switching supply, heavily filtered for EMI

-

Display Domain: Separate +12V or +24V rail to avoid introducing flicker or modulation into AFE

4.3 Military-Specific Oscilloscope Applications

| Use Case | Design Feature |

|---|---|

| EMP Test Scopes | Shielded power input, survives 50 kV/m transient field strength (MIL-STD-461G) |

| Underwater Weapon Monitoring | IP68-sealed power supply, operational to 500m depth for 30+ days continuously |

| Aerospace Avionics Platforms | Power system certified to DO-160G, full operation –55°C to +85°C, 70,000 ft alt. |

Reference: Tektronix Military Oscilloscope Power Design Notes

Download PDF

5.1 Decision Tree for Power Module Selection

🔧 Step-by-Step Criteria:

-

Electrical Performance

-

Efficiency ≥ 90%

-

Ripple < 10mVp-p (or <5μV/√Hz for sensitive loads)

-

Transient response < 100μs (25–75% load step)

-

-

Environmental Compatibility

-

MIL-STD-810H (vibration, shock, thermal cycling)

-

MIL-STD-461G (EMI/EMC)

-

IP68 / DO-160G for specific domains (underwater, avionics)

-

-

System-Level Factors

-

Redundancy requirements (N+1)

-

Scalability (modular parallel/series connection)

-

Weight & form factor (especially airborne/portable systems)

-

-

Lifecycle Cost (TCO)

-

Efficiency loss cost over 10 years

-

MTBF > 100,000 hours to reduce maintenance cycles

-

AI/diagnostic features for predictive maintenance

-

5.2 TCO Model: Conventional vs Modular Power

| Item | Traditional PSU | Modular Power Supply |

|---|---|---|

| Initial Cost (USD) | $800 | $1200 |

| Annual Power Loss (W @ 85%) | 200 | 80 |

| 10-Year Energy Cost | ~$2200 | ~$880 |

| Maintenance Downtime | 5× / 10 years | 1× / 10 years |

| Total Cost of Ownership (TCO) | ~$4200 | ~$2580 ✅ |

📘 Source: U.S. DoD Power Efficiency Metrics Guidebook, 2022 Edition

(Link)

5.3 Next-Gen Technology: GaN, SiC & Intelligent Power

GaN/SiC Power Devices:

-

Enable MHz-level switching

-

Reduce transformer/inductor volume >60%

-

Increase power density to >300W/in³

-

Improve thermal performance with low Rds(on)

AI-Enabled Smart Modules:

-

Built-in telemetry (voltage, current, temperature)

-

Support for predictive fault detection

-

Adaptive control algorithms for variable loads

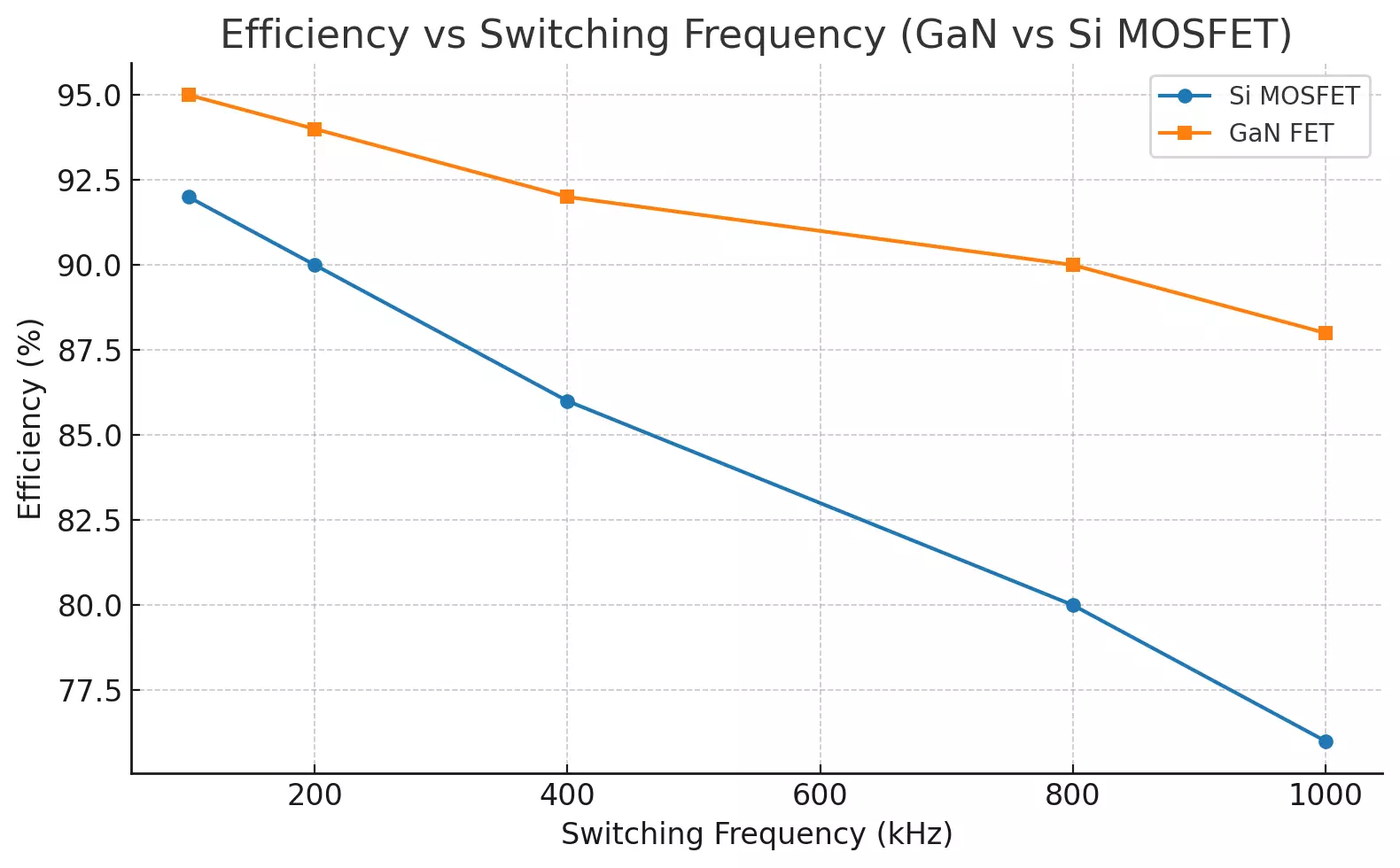

🔍 Efficiency vs Frequency Comparison:

(Refer to previous graph: "GaN vs Si MOSFET Efficiency")

-

GaN retains ≥88% efficiency at 1MHz

-

Si MOSFET drops below 80% beyond 800kHz

-

This makes GaN ideal for SWaP-constrained military platforms (Size, Weight, and Power)

Reference: Power Electronics News, “How GaN is Revolutionizing Military Power Supply Design”

Read Article

✅ 6. Conclusion

From phase-array radar to RF signal generators and high-precision oscilloscopes, military-grade testing equipment demands mission-critical reliability, minimal electrical noise, and robust environmental resilience. Modular power supplies deliver these capabilities while enabling scalability, maintainability, and future-readiness through GaN/SiC technology and intelligent diagnostics.

As modular design becomes the new baseline in defense R&D labs, the power supply is no longer a background component—it’s a strategic enabler of next-generation test and signal systems.