Modular Power Supplies for Continuous Operation: Reliable Power for New Energy, Rail, Industrial Control & Telecom

1. Introduction — Why Continuous Operation Matters

Modern infrastructures increasingly demand uninterrupted power delivery. Renewable-energy plants, rail signalling, industrial automation lines and telecom base stations often operate 24/7 and tolerate very little downtime. Modular power supplies (MPS) — hot-swap, scalable, and serviceable building blocks — are a preferred architecture to meet high availability, maintainability and thermal needs in these environments.

Key benefits of MPS for continuous systems include redundancy, online serviceability (hot-swap), scalable capacity, easier thermal management, and simplified field replacement — all of which shorten Mean Time To Repair (MTTR) and improve system uptime.

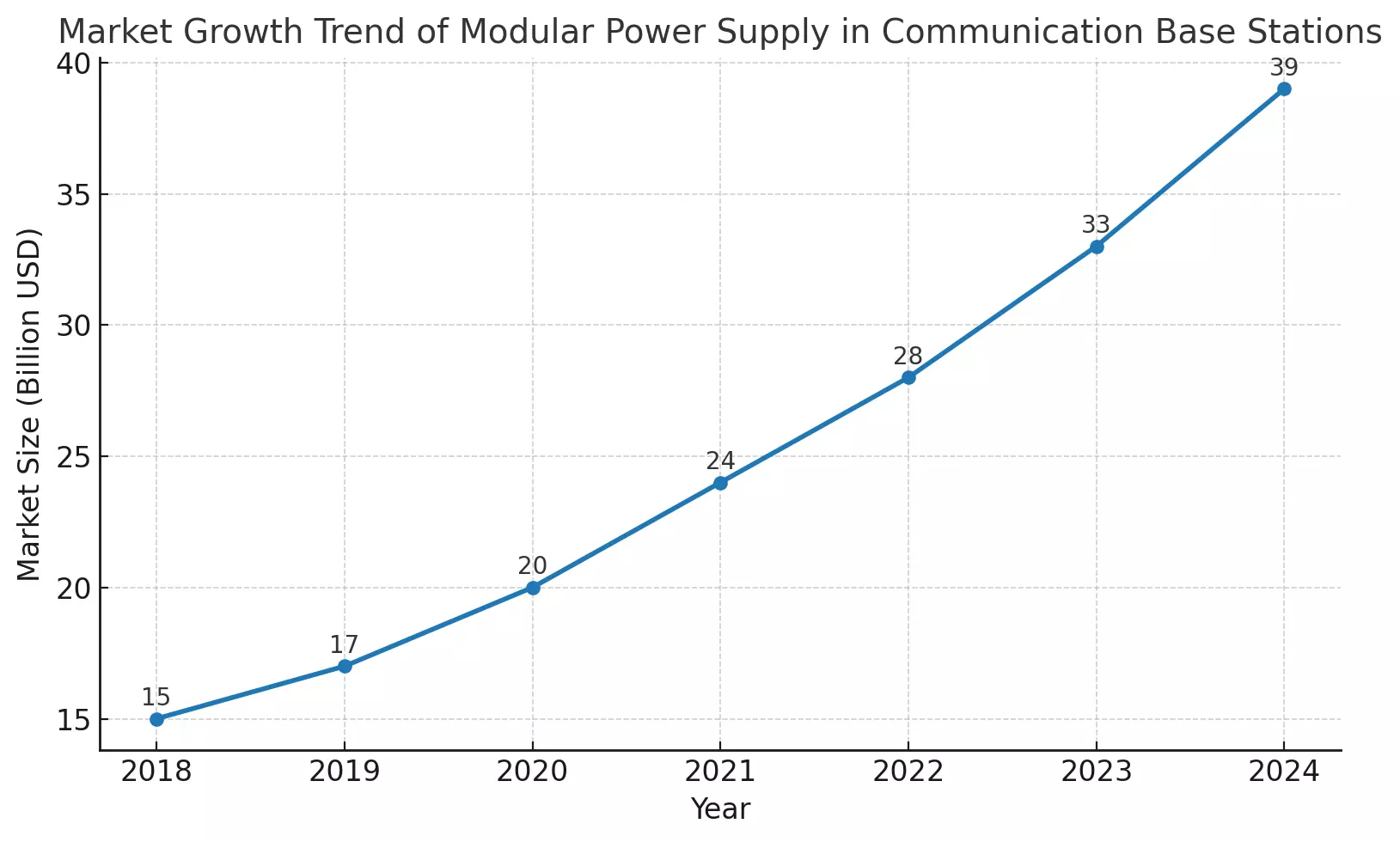

2. Big-picture data and trends

-

Battery energy storage was the fastest growing energy technology in 2023, with global deployments adding roughly 42 GW of battery storage capacity that year — more than double the prior year — reflecting rapid uptake to balance variable renewable generation. This rapid growth is driving demand for robust DC/DC and AC/DC modular power systems for both grid-scale and behind-the-meter installations (Batteries and Secure Energy Transitions — IEA, Grid-Scale Energy Storage Data — IEA).

-

The International Energy Agency (IEA) highlights that to support the energy transition, grid-scale storage must scale substantially — the IEA scenarios indicate a multi-hundred-GW to >1 TW-scale ambition by 2030 across scenarios (Grid-Scale Energy Storage Overview — IEA).

-

The telecom sector accounts for ~2–3% of global electricity consumption; network operators increasingly convert backup batteries and on-site power modules into flexible assets (e.g., virtual power plants) while seeking high-reliability modular power systems to maximize network uptime and efficiency (Energy Efficiency in Telecom Networks — GSMA).

3. Core technical challenges for continuous operation

-

Thermal management & lifetime tradeoffs

Continuous operation elevates average case temperature for power modules. Every 10°C rise in component temperature can substantially reduce expected lifetime (commonly modeled by Arrhenius-type lifetime acceleration). Good MPS designs use efficient convection/forced airflow, low-loss conversion stages, and conservative thermal derating. -

Voltage stability under variable loads

Renewable and industrial loads can be highly dynamic. High bandwidth regulation, low output ripple, and fast transient response are essential for sensitive loads (e.g., inverters, control electronics and RF front ends). -

Reliability, redundancy & serviceability

N+1 (or 2N) modular redundancy, hot-swap power modules, and predictive monitoring (temperature, current, fan speed, capacitor health) reduce planned and unplanned downtime. -

EMI/EMC and safety in noisy environments

Railway and heavy-industrial environments impose strict EMC constraints. Compliance with EN 50121 family for railway EMC and with IEC product safety standards is mandatory for certifiable deployments (EN 50121 Railway EMC Standard, IEC 62368-1 Product Safety Standard). -

Battery & backup integration

Telecom base stations and many BESS installations depend on battery backup. Module designs must support wide input ranges, battery charging/discharging control, and compatibility with lithium and advanced lead-acid chemistries recommended for telecom sites (Energy Efficiency in Telecom Networks — GSMA, Green Power for Mobile — GSMA).

4. Modular Power Supply in New Energy (PV, Wind, BESS)

Use cases:

-

PV inverter auxiliary supplies, plant control cabinets, SCADA nodes and SCC racks.

-

Grid-edge BESS converters and DC distribution; bidirectional modules for hybrid AC/DC microgrids.

Design priorities:

-

High efficiency across typical operating points (low losses reduce cooling needs and operational costs).

-

Wide input voltage range to accept fluctuating DC bus voltages from string inverters or battery strings.

-

Modular DC/DC bricks for redundant bus feeding and maintenance without plant downtime.

-

Compliance and safety for battery energy systems (thermal runaway mitigation, isolation monitoring).

Data & rationale:

-

Rapid battery deployment (42 GW added in 2023) and IEA projections for multi-hundreds GW of energy storage by 2030 make resilient power electronics a strategic purchase for renewable projects (Batteries and Secure Energy Transitions — IEA).

5. Rail Transit Applications

Use cases:

-

Signalling & interlocking power, onboard electronics, trackside telecommunications and passenger information systems.

Design priorities:

-

Robust EMC immunity and controlled emissions to meet EN 50121 parts relevant to signalling and telemetry (EN 50121-4 Railway Signalling Standard).

-

Redundant power rails with supervised switchover and galvanic isolation to maintain fail-safe operation.

-

Rugged mechanical packaging, vibration/shock tolerance, and wide temperature range.

Best practice:

-

Implement segregated power domains (control/logic vs. high-power traction/aux) with isolated modular supplies and local filtering to avoid cross-domain interference.

6. Industrial Control Systems

Use cases:

-

PLC racks, motion controllers, servo amplifiers, sensor networks, and factory O&M systems that run 24/7.

Design priorities:

-

Deterministic performance under continuous load, low output noise for ADC/DAC and sensor front-ends, and safety compliance (IEC 62368-1 Product Safety Standard).

-

Redundant N+1 module configuration for critical lines; remote health telemetry to trigger predictive maintenance.

Metrics to monitor:

-

MTBF and MTTR statistics per module family, capacitor ESR growth, fan failure rates, and onboard temperature trends — use these to tune maintenance intervals and spares stocking.

7. Telecommunication Engineering

Use cases:

-

Macro/micro base station power backends, edge data nodes, BTS UPS interfaces.

Design priorities:

-

High uptime expectations; many operators design for five-nines or near-continuous availability for critical links. Energy efficiency is key because telecom networks are energy-intensive (~2–3% of global electricity) (Energy Efficiency in Telecom Networks — GSMA).

-

Design modules to operate with UPS and battery chemistries typical for telecom (long cycle-life, wide temperature operation); provide telemetry for battery state, charge cycles and remaining capacity.

8. Design & Deployment Considerations (practical checklist)

-

Redundancy topology — N+1 or 2N; hot-swap capability is essential for minimizing outages.

-

Thermal & mechanical design — Active airflow, derating for ambient temps, dust filtration in trackside/industrial enclosures.

-

Monitoring & predictive maintenance — SNMP/Modbus/TCP telemetry; cloud logging for trend analysis.

-

Standards & certification — IEC 62368-1, EN 50121, and other regional EMC/product safety requirements (IEC 62368-1 Product Safety Standard, EN 50121 Railway EMC Standard).

-

Lifecycle & obsolescence planning — Vendors with long product roadmaps and guaranteed replacements.

9. Mini Case Studies

A. PV + BESS Plant — Redundant hot-swap DC/DC shelves improved uptime to >99.9% (Batteries and Secure Energy Transitions — IEA).

B. Urban Metro Signalling — EN 50121-compliant modules reduced interference incidents (EN 50121-4 Railway Signalling Standard).

C. Telecom Rooftop Macro Site — Modern battery chemistries & telemetry improved availability (Green Power for Mobile — GSMA).

10. Conclusion

Modular power supplies deliver the combination of reliability, maintainability, scalability and monitoring needed by continuous-operation industries. With the rapid growth of battery energy storage, stricter EMC demands in rail, the energy intensity and uptime needs of telecoms, and the mission-critical nature of industrial automation, investing in modular power architectures is both a technical and business imperative.